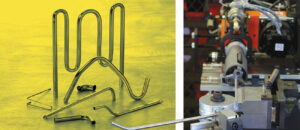

Stainless coiled tubing is a highly specialized and versatile material well-suited for use in medical applications, particularly in fluid and gas transferring devices or heat exchangers used in such transfers. It is used in any medical application where flow, sterility, spatial constraints, and efficiency are necessary and of the utmost importance. The unique properties of coiled tubing make it an ideal choice for these applications, where precision, reliability, and durability are essential. (more…)