High-Performance Custom Aluminum Tubing

Eagle Stainless is your trusted source for custom aluminum tubing, delivering precision-engineered solutions to meet the unique needs of industries such as aerospace, automotive, and medical manufacturing. Known for its lightweight yet durable properties, aluminum tubing is ideal for various applications, offering strength, corrosion resistance, and excellent thermal conductivity.

Alloys: 2024, 3003, 5052, 6061, 7075

Temper: 0, T3, T4, T6, H14

The exact properties of a given aluminum alloy also depend on its temper or heat-treatment history.

H – Strain Hardened 0 – Annealed T – thermally treated.

Why Choose Custom Aluminum Tubing?

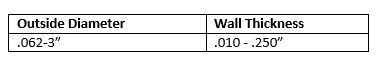

Custom aluminum tubing provides unparalleled flexibility for applications that demand precision and unique specifications. At Eagle Stainless, we offer tubing tailored to your requirements, ensuring optimal performance for your project. Whether you need a specific diameter, wall thickness, or finish, our team is equipped to deliver aluminum tubing that aligns perfectly with your vision.

Our custom tubing solutions stand out due to the following:

- Lightweight Durability: Aluminum combines strength with reduced weight, which is ideal for industries requiring efficiency and reliability.

- Corrosion Resistance: Suitable for challenging environments, our aluminum tubing resists wear and tear, ensuring longevity.

- Custom Configurations: We accommodate unique shapes, sizes, and finishes, creating tubing that fits seamlessly into your designs.

Applications of Custom Aluminum Tubing

Eagle Stainless aluminum tubing is trusted across industries for its versatility and performance. Common applications include:

- Aerospace Engineering: Lightweight components for aircraft structures and systems.

- Medical Devices: Lightweight, durable tubing is used in mobility aids and precision components for diagnostic equipment.

- Automotive Industry: Tubing supports heat exchangers and lightweight components for better cooling and fuel efficiency.

- Industrial Equipment – Aluminum tubing offers corrosion resistance for pneumatics and lightweight strength for robotics and automation.

Quality You Can Trust from Eagle Stainless

Eagle Stainless is committed to providing superior-quality tubing with the precision and consistency you need. Our custom aluminum tubing is manufactured to meet the highest standards, supported by ISO 9001 and ISO 13485 certifications. Whether you require standard tubing or a fully custom solution, our team is committed to delivering products that exceed your expectations.

Ready to find the perfect tubing for your project? Contact us today to learn more about our custom solutions and how we can support your needs.