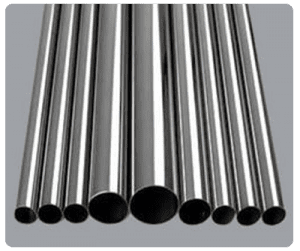

In some instances, the terms may be used interchangeably. However, one key difference between tube and pipe is particularly in how the material is ordered and toleranced. Tubing is used in structural applications, so the outside diameter becomes the critical dimension. Tubes are often used in applications such as medical devices that require precise outside diameters. The outside diameter is essential since it will indicate how much it can hold as a stability factor.

Meanwhile, pipes typically transport gasses or liquids, making it essential to know their capacity. Knowing how much can flow through the pipe is critical. The circular shape of the pipe makes it efficient when handling pressure from the liquid flowing through.

Classification of Tube vs. Pipe

Pipes are classified as schedule and nominal diameter. They are typically ordered using the Nominal Pipe Size (NPS) standard and by specifying a nominal diameter (pipe size) and schedule number (wall thickness). The schedule number can be the same on different-sized pipes, but the actual wall thickness will be different.

Tubes are typically ordered to outside diameter and wall thickness; however, they may also be ordered as OD & ID or ID and Wall Thickness. The strength of a tube depends on the wall thickness. A gauge number defines the thickness of a tube. Smaller gauge numbers indicate larger outside diameters. The inside diameter (ID) is theoretical.

Tubes can be square, rectangular, or cylindrical, whereas piping is always round. The circular shape of the pipe evenly distributes the pressure force. Pipes accommodate larger applications ranging from ½ inches to several feet, whereas tubing is generally used in applications where smaller diameters are required.

Ordering Your Tube and Pipe

When deciding between ordering pipe vs. tube, some notable distinctions come into play.

When deciding between ordering pipe vs. tube, some notable distinctions come into play.

Tubing is typically ordered according to outside diameter and wall thickness; however, it may also be ordered as OD & ID or ID and wall thickness. Although tubing has three dimensions (O.D., I.D. and wall thickness) only two may be specified with tolerances and the third is theoretical. Tubing is usually ordered and held to tighter and more stringent tolerances and specifications than pipe.

Pipe is typically ordered using the Nominal Pipe Size (NPS) standard and by specifying a nominal diameter (pipe size) and schedule number (wall thickness).

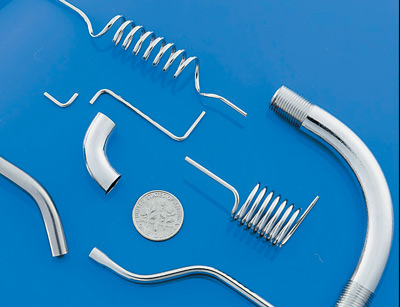

Both tubes and pipes can be cut, bent, flared, and fabricated – check out our top 10 tips for ordering tubing and piping.

Defining Tubing vs. Piping Characteristics

There are a few key characteristics that add to pipe and tube differences:

Shape

Pipe is always round. Tubes can be square, rectangular, and round.

Measurement

Tube is typically ordered outside diameter and wall thickness. Tubing is usually held to tighter and more stringent tolerances and specifications than pipe. Pipe is generally ordered using the nominal pipe size (NPS) standard and by specifying the nominal diameter (pipe size) and schedule number (wall thickness)

Telescoping Abilities

Tubes can be telescoped. Telescoping tubes are perfect for applications where different pieces of material are sleeved or expanded inside one another.

Rigidity

Pipe is rigid and cannot be shaped without special equipment. Except for copper and brass, tubes can be shaped with some effort. Bending and coiling tubing can be done without excessive distortion, wrinkling, or fracturing.

Applications

Tubes are used in applications such as medical devices that require a precise outside diameter. The outside diameter is important since it indicates how much it can hold as a stability factor. Pipes are used for transporting gases or liquids, making the capacity important. The circular shape of the pipe makes it efficient when handling pressure from the liquid flowing through.

Metal Types

Tubes are cold-rolled and hot-rolled. Pipe is only hot rolled. Both can be galvanized.

Size

Pipes accommodate more extensive applications. Tubing is generally used where small diameters are required.

Strength

Tubes are stronger than pipes. Tubes perform better in applications that require durability and strength.

Contact the Experts at Eagle Stainless

For over 35 years, Eagle Stainless has established itself as a premier provider of high-quality tubing components and parts. With a strong presence in the global industrial, energy, medical, and aerospace sectors, we take pride in our reputation for excellence. If you are seeking a product quote or wish to delve deeper into the nuances of tube versus pipe specifications, click below or contact us to start your exploration journey with us today!