Eagle Stainless has increased our capabilities for bending stainless steel tubing with a new CNC tube bending machine. This gives additional capacity as well as increased CNC tube bending through .625 diameter in a variety of wall thicknesses, with minimal radius and wall thinning requirements. The machine assures consistent bending and precision dimensions.

Considerations for bending stainless steel tubing include the bend radius, yield strength, material thickness and whether the material is welded or seamless. Precision bent components are ideal for uses in surgical devices, heat exchangers, instrumentation, and handling equipment. With 40 years of experience, Eagle has the ability to bend tubes in multiple directions and angles without excessive distortion, wrinkling or fracturing. The medical device industry demands quality and precision. This is mirrored by Eagle’s commitment to quality reflected by their ISO 9001 and ISO 13485 quality management certifications.

4 Considerations Before Bending Stainless Steel Tubing

1. Bend Radius

The bend radius is measured to the inside curvature, it is the minimum radius one can bend a tube or pipe without kinking or damaging the tube. Eagle size range from .032” to 1” diameters with a variety of wall thickness, with minimal radius and wall thinning requirements.

2. Yield Strength

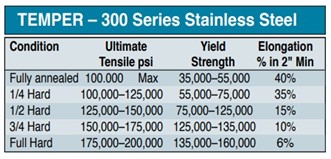

2. Yield Strength

Yield strength is the maximum stress that can be applied to a tube before causing damage. The yield strength is determined using a tensile test. The results of the test are plotted on a stress-strain curve. Where the stress-strain curve deviates from proportionality is the yield strength of the material.

3. Material Thickness

Tube wall thickness is gauge. The lower the gauge number, the thicker the wall thickness. The wall thickness (ratio between OD and WT) is another factor. Thin wall material may require more support when bending. As the wall gets thicker, the amount of pressure the tubing can withstand increases while the amount of flow decreases.

4. Welded or Seamless Tubing

Welded tubing is produced by having a flat stainless strip roll formed. Seamless tubing is molten stainless steel formed into a billet. The billet is then extruded and turned into a hollow tube. Both welded and seamless tubing can be bent. When the radius is very tight, seamless could be the better option.

To learn more about bending stainless steel tubing and our capabilities at Eagle Stainless, please contact us today!