Eagle Stainless is a leading supplier of ultra-high precision, cut-to-length, stainless steel tubing and bar for medical, electronic, semi-conductor, industrial and aerospace applications. We offer cutting and metal deburring services to serve our customers varying needs .Deburring tubing not only improves safety and aesthetics but also enhances its functionality and corrosion resistance

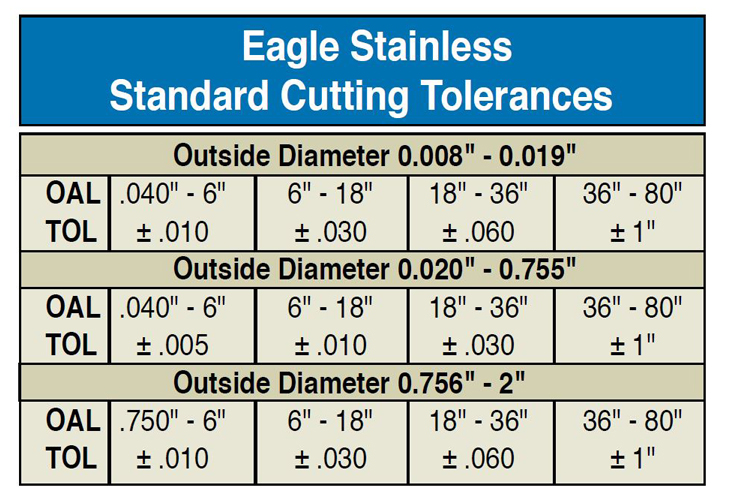

Our manufacturing facilities enable us to cut and deburr up to 2″ diameter tubing in quantities from a single piece to millions of pieces or more… and from lengths of .008″ and longer with standard tolerances (see cutting tolerances below). Closer tolerances are certainly possible, simply request a quote with the details of your application, and we’ll be glad to help.

Cutting stainless steel tubing without burrs is essential to ensure safety, maintain efficiency, prevent contamination, and meet quality standards in a wide range of applications. It is a critical factor in ensuring the performance, reliability, and longevity of stainless steel tubing systems.

Specifications

| Alloy | ||

|---|---|---|

| Stainless Steel T304 T316 | ||

| Aluminum Alloys Nickel Alloys 200 400 600 625 800 X750 C276 Copper Brass and more… just ask! |

| Minimum Outer Diameter (OD) | Maximum Outer Diameter (OD) |

|---|---|

| 0.004in | 24in |

| Minimum Length | Maximum Length |

|---|---|

| .008 | 20ft |

Secondary Operations

| Welding & Brazing | Assembly |

|---|---|

| Welding brazing or soldering of standards or custom-made components to customer drawings or specifications are performed on state-of-the-art equipment including computer-controlled, laser machining centers | Assembly of multiple parts to achieve a single component can be accomplished by various methods such as welding, threading, epoxy, etc. Eagle works to exact customer specifications, as well as the recommendations of our engineering experts, to achieve the lowest costs and the highest quality |

Equipment/Processes

| Capabilities | |

|---|---|

| Bending / Coiling Flaring / Flanging EDM (wire and ram type) CNC Screw Machine Sand / Grit Blasting Bulging Nothing / Slotting Assembly Re-drawing End Forming Swaging Centerless Grinding Welding / Brazing Laser Welding |

Laser Cutting Laser Notching Laser Etching Electropolishing Passivation Annealing Radius End Closures Spherical Pointed or Flat End Closures General Machining Drilling / Reaming Deburring Honing Bevel Cutting Threading |